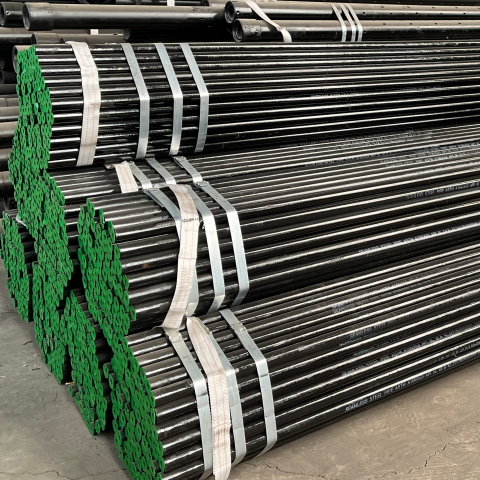

Because steel pipes are prone to chemical or electrochemical reaction and corrosion due to the impact of the use environment and transmission medium during use and transportation, the use of steel pipe anti-corrosion paint is an effective method to prevent steel pipes from corrosion.

Based on the analysis of the status quo of the anti-corrosion coating process for steel pipes, there are mainly four kinds of factory automatic coating processes for welded pipes, oil casings and other seamless steel pipes commonly used at home and abroad:

Anti corrosion coating process I of steel pipe: spray coating method shall be adopted, and straight line transmission shall be conducted before, after and in the middle of coating to form coating film. Then the shift fork is transferred, the hook chain is rolled for transportation, and the steel pipe enters the steam oven horizontally for heating and drying

Anti corrosion coating process II of steel pipes: electrostatic coating method is adopted. Before, after and in the middle of coating, inclined roller passes are used for spiral transmission to form a coating film. Then the screw lift is transferred and lifted to the rack for cooling and natural drying

Steel pipe anti-corrosion coating process III: steel pipe is transported in a straight line, using UV coating system, vacuum coating method, and air flow washing to form a coating film. Immediately after the coating, carry out U Ⅳ radiation curing coating. The characteristic is that the formation and curing of the coating film are completed between two wheels of the steel pipe anti-corrosion coating process IV: the heating airless spraying method is used for coating, and the wheel channel shall be used for transportation before coating, and the synchronous "V-shaped tooth" chain shall be used for transportation after coating to form the coating film. After coating, the steel pipe is transferred from the stepper to the horizontal "V-tooth" chain conveyor and enters the steam drying oven for heating and drying

How to drill holes in ASTM A179 seamless steel pipes?

How to drill holes in ASTM A179 seamless steel pipes?

What are the advantages of cold drawn ASTM A192 seamless steel pipe?

What are the advantages of cold drawn ASTM A192 seamless steel pipe?

How to drill holes in ASTM A53 seamless steel pipes?

How to drill holes in ASTM A53 seamless steel pipes?

What is the function of an extruded ASTM A106 seamless steel pipe?

What is the function of an extruded ASTM A106 seamless steel pipe?