API 5L Gr.B X42 Seamless Carbon Steel Line Pipe For Natural Gas

API 5L X42 PSL1 and PSL2 Line Pipe Detailed Specifications

API 5L X42 steel pipes are manufactured in accordance with API Spec 5L and are used for pipelines transporting natural gas, water, petroleum and petroleum industries, including low and medium pressure vessels and boilers. According to the material classification, it is a kind of carbon steel pipe. The manufacturing methods include seamless pipe and welded pipe.

Standard packaging of API 5L X42 Seamless Pipe and ERW Pipe is available in bundles or bulk form. Use special packaging, iron bars, pallets, metal or wood for fastening. If you have special requirements for packaging methods, please inform us in the quotation.

API 5L X42 Seamless Pipe Chemical Composition:

| PSL |

Steel

grade |

API 5L X42 Seamless Pipe Chemical composition (%) |

| C |

Mn |

P |

S |

Ti |

| Max |

Max |

Max |

Max |

Max |

| PSL1 |

B |

0.28 |

1.20 |

0.030 |

0.030 |

0.04 |

| X42 |

0.28 |

1.30 |

0.030 |

0.030 |

0.04 |

| PSL2 |

B |

0.24 |

1.20 |

0.025 |

0.015 |

0.04 |

| X42 |

0.24 |

1.30 |

0.025 |

0.015 |

0.04 |

API 5L X42/L290 ERW Pipe Chemical Composition

| API 5L X42 ERW PIPE CHEMICAL COMPOSITION |

| C |

Mn |

P |

S |

V |

Nb |

Ti |

| max. |

max. |

max. |

max. |

max. |

max. |

max. |

| 0.26 |

1.20 |

0.030 |

0.030 |

c,d |

c,d |

d |

API 5L X42 Seamless Pipe Mechanical Properties

| PSL |

Steel

grade |

Mechanical properties |

| Yield strength |

Tensile strength |

Elongation |

| MPa |

MPa |

(%) |

| Min |

Max |

Min |

Max |

| PSL1 |

B |

241 |

|

414 |

|

See API SPEC 5L |

| X42 |

290 |

|

414 |

|

| PSL2 |

B |

241 |

448 |

414 |

758 |

See API SPEC 5L |

| X42 |

290 |

496 |

414 |

758 |

Mechanical properties

| Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 1 |

Seam of Welded Pipe |

| Yield Strength a |

Tensile Strength a |

Elongation |

Tensile Strength b |

| Rt0,5 PSI Min |

Rm PSI Min |

(in 2in Af % min) |

Rm PSI Min |

| 30,500 |

48,600 |

c |

48,600 |

| 35,500 |

60,200 |

c |

60,200 |

| 42,100 |

60,200 |

c |

60,200 |

| 46,400 |

63,100 |

c |

63,100 |

| 52,200 |

66,700 |

c |

66,700 |

| 56,600 |

71,100 |

c |

71,100 |

| 60,200 |

75,400 |

c |

75,400 |

| 65,300 |

77,500 |

c |

77,500 |

| 70,300 |

82,700 |

c |

82,700 |

| a. For intermediate grade, the difference between the specified minimum tensile strength and the specified minimum yield for the pipe body shall be as given for the next higher grade. |

| b. For the intermediate grades, the specified minimum tensile strength for the weld seam shall be the same as determined for the body using foot note a. |

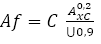

| c. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation: |

|

| Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units |

| Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches) , as follows |

| – For circular cross-section test pieces, 130mm2 (0.20 in2) for 12.7 mm (0.500 in) and 8.9 mm (.350 in) diameter test pieces; and 65 mm2 (0.10 in2) for 6.4 mm (0.250in) diameter test pieces. |

| – For full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2) |

| – For strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2) |

API 5L Grade L290 ERW Pipe Mechanical Properties

| Yield Strength |

Tensile Strength |

ELONGATION |

| Mpa(psi) |

Mpa(psi) |

| min |

min |

min |

| 245(35 500) |

415(60 200) |

28% |

Impact Test

| IMPACT TEST OF API 5L X42 Line Pipe |

| AVG. ABSORBED ENERGY |

IND. ABSORBED ENERGY |

| Min.(joules) |

Min.(joules) |

| 27 |

20 |

API 5L Gr.B X42 Seamless Carbon Steel Line Pipe For Natural Gas,ANSI / API 5L specifies the manufacture of two product levels (PSL1 and PSL2) Shengtian Group is a professional supplier of API 5L , X42 – X70, and 4-1/2" to 20" ERW line pipe, steel grades A and B.